-

Shopping Tools

-

Care & Maintenance

-

About

-

Dealer Login

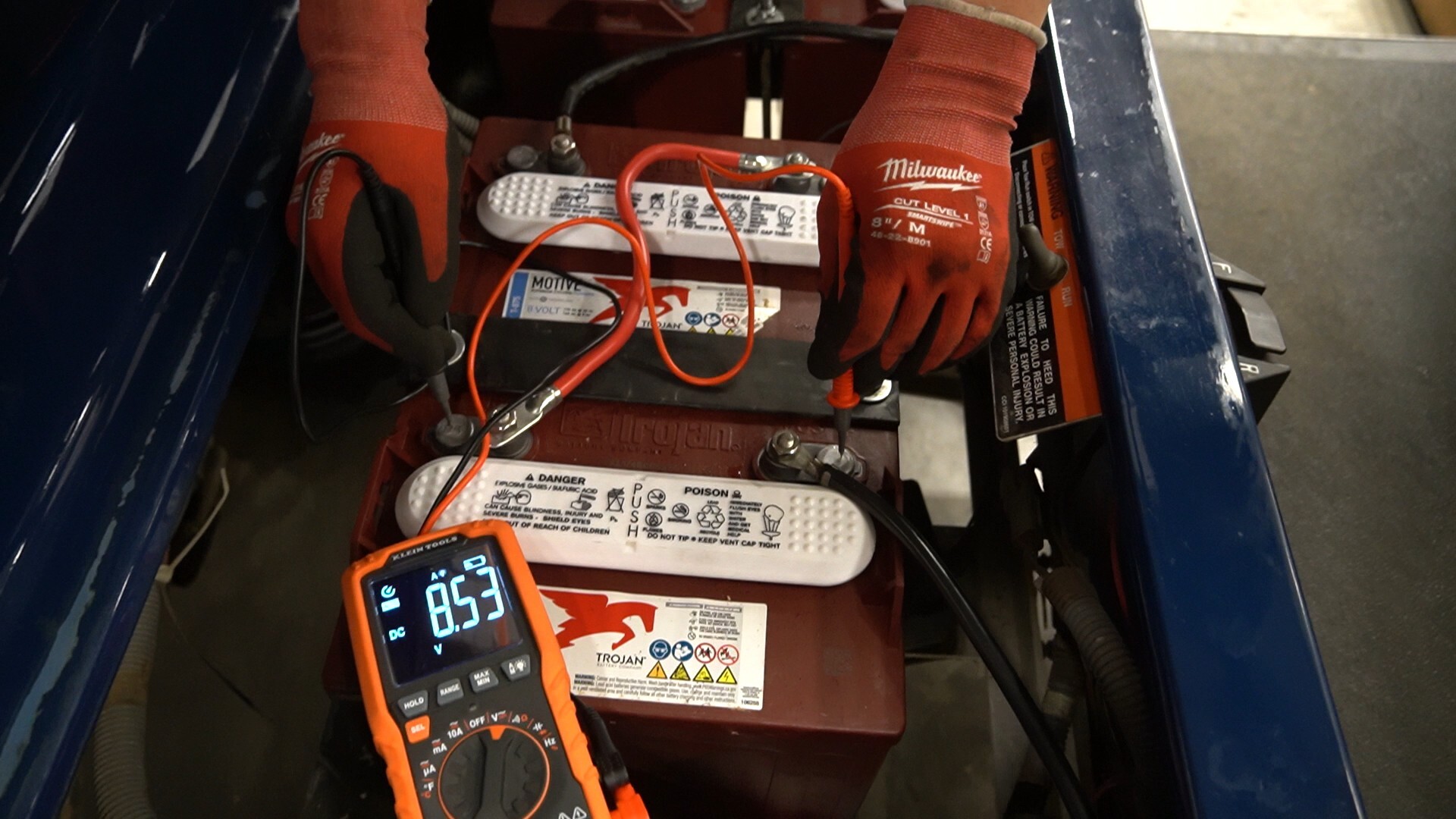

To verify real battery health fast: fully charge, clamp a 6-V tester to one battery, apply a 10–15 s load, and confirm voltage remains above the maker’s spec.

Whether you maintain one cart or a small fleet of golf carts, a 6-volt load tester is the quickest way to find weak batteries that hide behind “OK” resting voltage. This guide explains the right setup, a precise step-by-step process, and how to read results accurately—so you can keep range strong and downtime low.

Open-circuit voltage shows state of charge; a load test shows capacity under stress. A healthy 6-V deep-cycle battery will hold voltage for 10–15 seconds at the tester’s rated load (often ~75–150 A for 6-V units) at room temperature. Weak batteries sag quickly and recover slowly.

Always compare to the manufacturer’s spec. As a practical field guide at ~77°F (25°C) under an appropriate load:

| Loaded Voltage (≈15 s) | Likely Condition* | Action |

| ≥ 5.3–5.4 V | Good / strong | Return to service; recheck on routine schedule. |

| ≈ 5.1–5.3 V | Serviceable | Keep in service; monitor more frequently. |

| < 5.0–5.1 V | Weak / failing | Try a conditioning charge; plan replacement if low under-load voltage persists. |

*Guidance only—use the battery brand’s published thresholds when available.

A proper 6-V load test—charge, rest, clamp, load for 10–15 seconds, then compare voltage to spec—reveals battery strength that a simple meter can’t. Log each battery, address weak units before they pull the pack down, and maintain clean connections. Used routinely, this simple procedure preserves range, boosts reliability, and extends the service life of your cart’s power system.