-

Shopping Tools

-

Care & Maintenance

-

About

-

Dealer Login

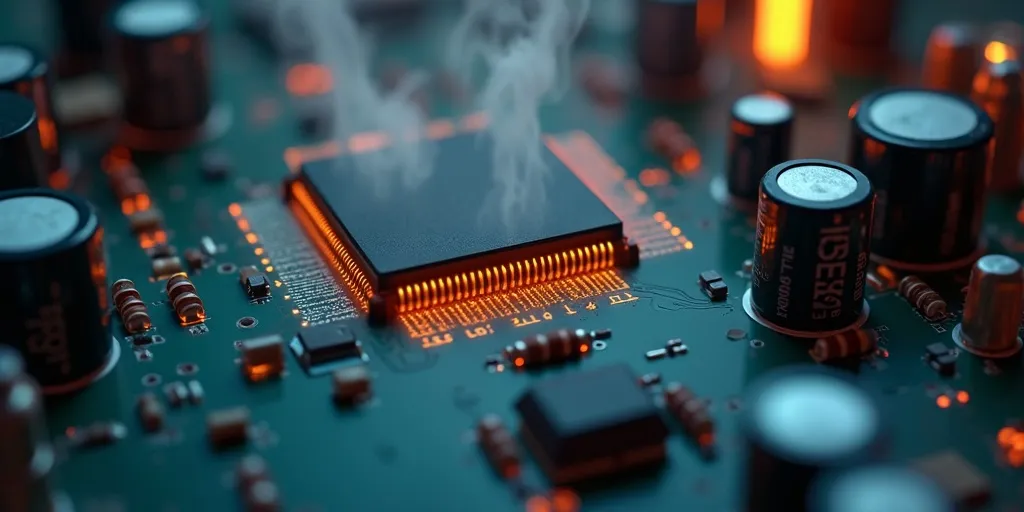

Controller running hot? Heat usually comes from high current, weak airflow, or resistance in the power path. Use this guide to find the cause and cool it down.

If your golf cart suddenly throws thermal cutbacks or the controller case feels too hot to touch, you’re seeing energy converted to heat instead of motion. That’s typically a mix of electrical resistance, heavy loading, and inadequate heat shedding. The good news: most causes are diagnosable with simple checks and a logical process.

De-energize the cart and disconnect the pack. Check battery posts, main positive/negative leads, controller B+ and B−, M-, and motor terminals. Look for discoloration, soot, melted jacket, or green/white corrosion. Re-crimp or replace heat-damaged lugs, clean mating surfaces to bright metal, and torque to spec. Verify cable gauge is appropriate for your controller’s peak current.

Warm components telegraph with smell and feel. After a short, moderate-drive test, carefully scan (non-contact thermometer works great): cables, solenoid, motor case, brake drums, and wheel hubs. Hot brakes indicate drag; a very hot motor or solenoid points to overcurrent or sticking. Fixing these upstream issues reduces controller heat dramatically.

Note gradients, payload (passengers, bags, tools), and tire setup. Oversize or underinflated tires raise rolling resistance; set pressures to manufacturer guidance. If you’ve added accessories or run hilly routes, consider dialing back acceleration, enabling a gentler torque curve, or choosing routes that avoid long continuous climbs. Small gearing changes (where applicable) can reduce sustained current.

If your controller uses a separate heat sink, remove it (with power isolated), clean old compound from both surfaces with isopropyl alcohol, and apply a thin, even layer of fresh thermal paste before reassembly. Ensure the heat sink and any shroud/fan are clean and firmly mounted. A few minutes with compressed air to clear fins often drops peak temps noticeably.

A tired cooling fan, cracked shroud, failing solenoid, or heat-baked cables will keep heat high. Replace like-for-like with correct ratings. If your application routinely exceeds the controller’s thermal envelope—steep terrain, heavy payloads, or performance motors—step up to a higher-amp controller designed with larger heat sinks or integrated active cooling.

If thermal cutouts persist after basic fixes—or you notice rapid temperature spikes with light loads—have a technician evaluate the controller and motor together. Intermittent MOSFET failures, sensor faults, or mis-calibrated current limits can mimic simple overheating but require specialized testing tools to confirm.

Controllers get hot when current is high, cooling is weak, or resistance wastes energy. Tackle those three levers—healthy batteries and connections, clean cooling, and realistic load/settings—and your system will run cooler, last longer, and deliver more reliable performance every round.