-

Shopping Tools

-

Care & Maintenance

-

About

-

Dealer Login

Grinding, humming, and a steering shimmy are hallmark signs a wheel hub is failing. Use this guide to confirm the fault on your golf cart, avoid misdiagnosis, and plan a safe repair.

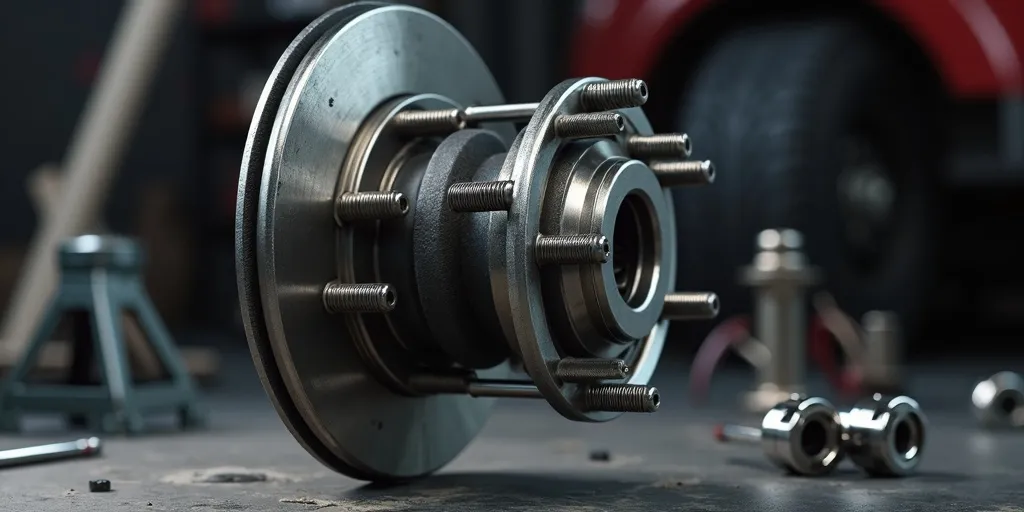

Most hubs use either a serviceable tapered-bearing pair (clean, repack with high-temp grease, set preload) or a sealed hub/bearing assembly (replace as a unit). If you find pitting, discoloration (blueing), or excessive play, replacement is the reliable route. Always replace damaged seals and torque fasteners to spec. After any hub work, verify toe alignment and tire pressures to protect your new parts and restore smooth steering.

How long can I drive with a noisy hub?

Not recommended. Bearings can seize or disintegrate, risking wheel loss or brake damage. Diagnose and repair promptly.

Do I need to replace both hubs?

If one side failed due to age or contamination, the other may be close behind. Many owners replace in pairs to restore symmetry and reduce downtime.

Why did my new bearing fail early?

Common causes include incorrect torque/preload, contaminated grease, misaligned components, or persistent tire imbalance creating excessive vibration.

A failing wheel hub announces itself with growls, vibration, and wobble—yet tires, brakes, and alignment can produce similar symptoms. Use the play test, spin-and-listen, gentle swerves, and heat comparison to pinpoint the fault. Fix promptly, torque correctly, and keep tires aligned and inflated. Your golf cart will steer straighter, ride quieter, and protect its new hub for the long run.